-

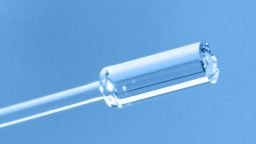

End Cap for Multimode Fibers

For small fiber core Diameters with high power density dominate fiber connectors with a cylindrical end cap made of quartz glass currently. This end cap is larger than the fiber core and is spliced to the optical fiber. In doing so, the laser beam is focused onto the fiber core via the end surface of the quartz cap, where, at the same laser power, the power density is significantly lower. -

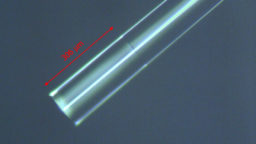

End Cap for Singlemode Fibers

During coupling into a singlemode fiber, the laser beam is focused into the fiber core, resulting a high power density on the facet. This is higher the smaller the fiber core and larger the laser power. To reduce the power density, an end cap will be spliced on the fiber facet. The laser beam is focused on the fiber core over the end face of this end cap, where at the same laser power, the power density is significantly lower. -

Mode Stripping

The mode stripper is installed in the connector body and removes the cladding modes over a certain length. The required length is defined according to the coupling properties (spot size or NA difference). The mode stripper ensures that the beam profile at the fiber exit looks optimal. The stripped cladding modes are converted into heat in the connector body. -

Fiber Monitoring

This safety system monitors temperature and possible fiber breakage as well as connectivity. This can happen if the fiber was bent too tightly or torsedtoo much during the application or was mechanically damaged altogether.